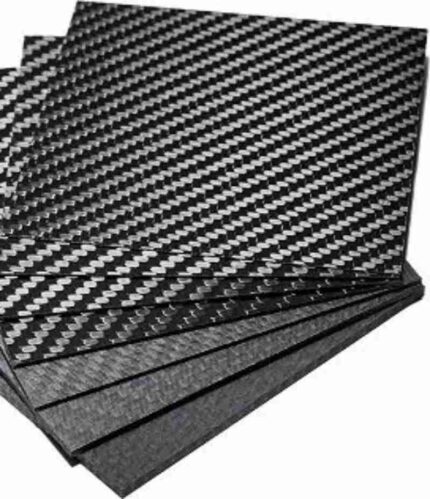

Rigid Graphite Felt

The production process of rigid graphite felt adopts professional technology and integrates graphite paper, graphite felt, and carbon cloth through a unique method. It is then cured and formed, followed by secondary high-temperature purification.

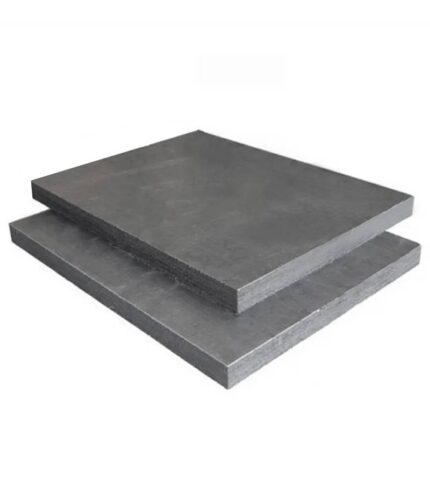

Graphite hard felt exhibits high purity and a rich carbon content, showcasing excellent ablative resistance and thermal shock resistance. Its air scouring, heat insulation, and heat preservation performance are also outstanding. It is primarily used in ultra-high temperature vacuum high-pressure sintering furnaces, as well as in the electronics, semiconductor industries, solar photovoltaic sector (including polycrystalline casting furnaces and single crystal furnaces), and other vacuum industrial furnace equipment within the graphite carbon industry.

Rigid graphite felt is a kind of high-performance material that combines graphite paper, graphite felt and carbon cloth into one body by a special process, and is prepared by secondary high-temperature purification. With its high purity and carbon content, rigid graphite felt shows excellent ablative and thermal shock resistance, as well as excellent performance in airflow scour, heat insulation, and insulation.

| Material | PAN / Pitch / Rayon |

| Bulk Density (g/cm3) | 0.15 - 0.28 |

| Thermal Conductivity W/m.k | 0.15 - 0.25 (25℃), 0.35 - 0.55 (1550℃) |

| Carbon (%) | ≥99 |

| Compressive Strength MPa | ≥0.3 |

| Ash (ppm) | 300 - 800 |

| Processing Temperature | ≥1800 |

| Board Specification | Length (mm) | 10 - 3000 |

| Wide (mm) | 10 - 2000 | |

| Thickness (mm) | 5 - 300 | |

| Operating Condition | Diame (mm) | Φ100 - φ2500 |

| Wall Thickness (mm) | 5 - 150 | |

| High (mm) | 100 - 3000 | |

| Tube Materials Spec | In the Air (℃) | ≤350 |

| In the Vacuum (℃) | ≤2200 | |

| In the Inert Atmosphere (℃) | ≤3000 |

* The ash value of this table is the standard product, if you need high purity products can provide purification treatment, purified ash ≤200PPm.

* The above data are only for reference, not guaranteed data.

Applications:

The hard properties of graphite hard felt make it mainly suitable for ultra-high temperature vacuum high-pressure sintering furnaces, electronics, semiconductor industries, and solar photovoltaic fields (including vacuum industrial furnace equipment such as polycrystalline casting furnaces and single crystal furnaces). Its excellent performance is fully utilized in these high-temperature and high-pressure environments to ensure the stable operation of the equipment.

Compared to other materials, our graphite felt is lightweight, flexible, and easy to install, while offering a variety of sizes and shapes to meet the specific needs of our customers. Its advantages of environmental protection, high cost effectiveness and low maintenance cost make it an ideal choice for all walks of life.

Customized service:

Our professional team is ready to provide our customers with the best type of graphite felt to meet their needs, whether for thermal insulation or other industrial applications. We are committed that our graphite felt is manufactured to the highest quality standards and is rigorously tested to ensure compliance with industry standards. Choose graphite hard felt for superior performance and reliable quality.