Carbon Light Therapy Rod

High-Purity Graphite Products and Service

We classifies graphite materials with carbon content > 99.9% as high-purity graphite.

It is mainly used in semiconductor-grade high-purity graphite materials, graphite rods for spectral analysis, graphite crucibles for precious metal smelting, graphite boats for lithium battery anodes, single crystal furnaces in the photovoltaic industry, and other fields.

In addition, we offer graphite purification services tailored to meet customers' specific requirements for impurities or purity levels. Depending on the different use environments, the purification requirements are usually ≤100ppm, ≤50ppm, ≤20ppm, ≤10ppm, ≤5ppm, ≤2ppm, and other different standards.

SHJ High-Purity Graphite Products

Graphite Spectral Rods For Spectral Analysis

Spectral rods refer to special graphite electrodes used for spectral analysis. Graphite can be used for spectrochemical analysis of all elements except carbon, and can be applied in fields such as emission spectroscopy, atomic absorption spectroscopy, and gas analysis. Spectral analysis graphite electrodes are made from low-ash, high-quality petroleum coke as the raw material, through calcination, crushing, kneading, baking, impregnation, graphitization, and purification. Currently, we can generally achieve ash content of ≤5PPM or less, and adopt cleanroom dust-free packaging to ensure that the product meets the high purity requirements of spectral analysis applications.

We have many standard sizes in production, such as ∮6300, ∮8300, ∮10300, ∮13300, ∮15*300, etc., to facilitate customers' selection.

Graphite Products For Semiconductor Industry

Components used in the semiconductor environment have extremely high requirements for particle size. Not only do they need to utilize the excellent physical properties of graphite such as high temperature resistance, corrosion resistance, and plasma resistance, but there are also high demands for the purity and processing accuracy of graphite.

We adopt internationally renowned imported purification equipment, which can extract the purity of graphite processing parts to 5-50ppm, and the ash content of specially customized products can reach below 2PPM.

Main Applications:

Graphite thermal fields in single crystal furnaces for PV applications, including heating elements, crucibles, insulation cylinders, packaging fixtures, etc.

Graphite Products For Photovoltaic Industry

High-purity graphite products play a crucial role as fundamental materials in the photovoltaic industry, finding extensive applications in every aspect of the sector.

Due to its high density and compressive strength, graphite material exhibits numerous advantages, including resistance to high temperatures and corrosion, superior electrical conductivity, and stable performance. Consequently, it is widely used in various critical processes, ranging from silicon ore smelting and polysilicon production to polysilicon ingot casting and direct pull single crystal growth.

To meet the stringent purity requirements of the photovoltaic industry for graphite materials, we are capable of elevating the purity level of graphite processed components to 5-50ppm, while specially customized products can achieve an extremely low ash content of below 2PPM.

These high-purity graphite products are primarily used in the manufacture of graphite electrodes, heaters, crucibles, vortex enhancers, thermal insulation shielding plates, heat reflecting plates, and various other items. Together, they provide strong support for the sustainable development and technological advancement of the photovoltaic industry.

High-Purity Graphite Powder

"Carbon Material for Third - Generation Semiconductor Crystal Growth - High-purity Graphite Powder."

Particle size: 35±5 micrometers;

Packaging: Minimum order quantity is 5 kilograms;

Application:

High-purity silicon carbide powder is the raw material for the growth of silicon carbide by the physical vapor transport (PVT) method, which is synthesized from high-purity graphite powder and silicon powder.

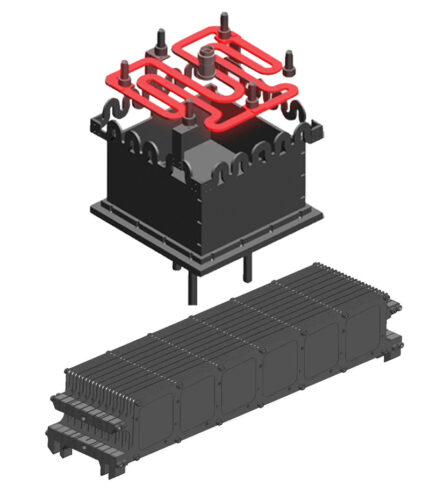

To meet the demand for the growth of silicon carbide single crystals, the silicon carbide powder synthesis equipment becomes particularly important. The role of high-purity graphite powder lies in: in this equipment, high-purity graphite powder reacts directly with silicon powder under high-temperature conditions, generating silicon carbide powder through precise high-temperature synthesis technology.

The technical difficulties of the synthesis equipment mainly lie in high-temperature and high-vacuum sealing and control, vacuum chamber water cooling, vacuum and measurement systems, electrical control systems, as well as heating and coupling technology for powder synthesis crucibles. By overcoming these technical challenges, the purity of the synthesized powder can reach an astonishing 99.9995%, providing an excellent crystal quality foundation for subsequent silicon carbide growth.