C/C Composite Cylinders

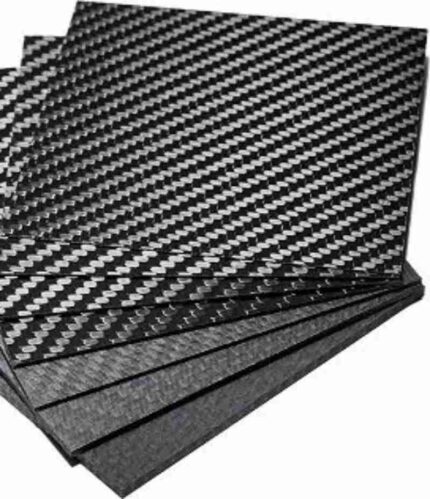

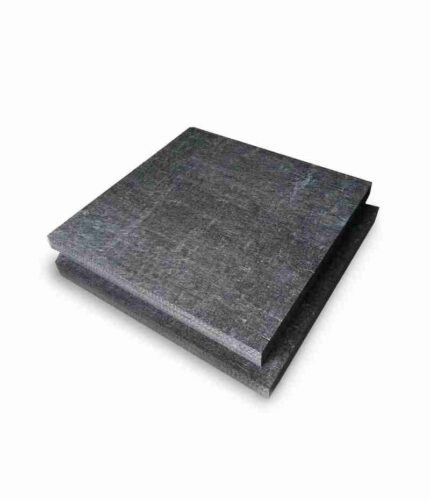

Carbon Carbon Composite | C/C Composite Cylinders

Applications

SHJ supplies CFC Cylinders with high quality properties, which are particularly suitable for applications in high temperature environments, such as performing hot pressing of tungsten carbide or ceramics. Cylinders made of these carbon-carbon composites are also used as holding drums in czochralski silicon crystal growth furnace for the production of monocrystalline silicon. In addition, carbon-carbon composites are often used as heat shields to protect equipment from the direct effects of high temperatures.

Features

CFC Cylinders are high strength, lightweight and long-service life. They can be manufactured in large sizes and diameters with high strength and thin wall characteristics. In addition, these cylinders can be customized into polygonal shapes.

Specifications

| Material | C/C | C/C | C/C | C/C | |

| Bulk Density | g/cm³ | 1.3 | 1.4 | 1.45 | 1.6 |

| Compressive Strength | MPa | ≥100 | ≥150 | ≥150 | ≥150 |

| Flexural Strength | MPa | ≥120 | ≥120 | ≥150 | ≥150 |

| Tensile Strength | MPa | ≥60 | ≥80 | ≥80 | ≥100 |

| CTE | 10-6/℃ | ≤4 | ≤4 | ≤4 | ≤4 |

| Thermal Conductivity (@1000℃) | W/(m.k) | 20-30 | 20-30 | 20-30 | 20-30 |

| Ash | ppm | <200 | <200 | <200 | <200 |

| Maximum Size | mm | φ1800*φ1400*1800 | |||

*The parameters in this table are for standard products. If high purity products are required, purification treatment can be provided, with a purified ash content of ≤20PPM maximum.

*The above values are typical, not guaranteed.

*Special needs and high-end series products can be customized through negotiation and communication with our company.