Carbon-Carbon Composite Materials

About C/C Composite Materials

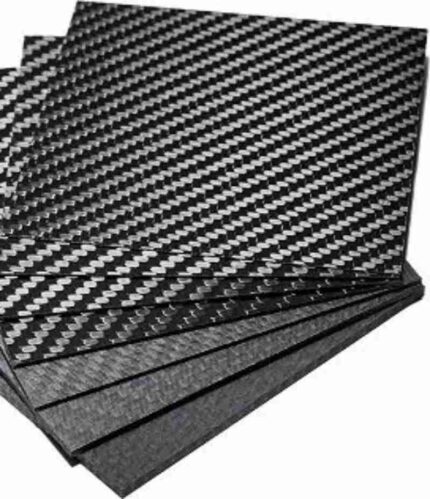

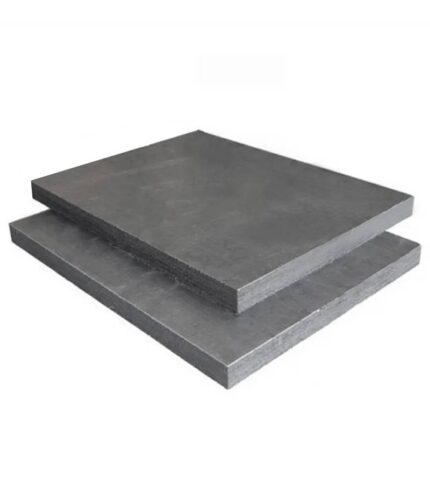

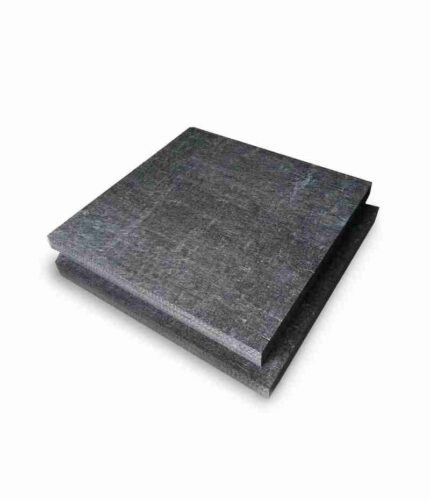

Carbon-carbon composites are high-performance composite materials made of carbon fiber and carbon matrix. This kind of material has excellent properties such as lightweight, high strength, high stiffness, high-temperature resistance and corrosion resistance. It is an advanced material that can work stably in high-temperature environments exceeding 3,000°C. They can be used for insulation, heat insulation, and heat preservation.

They not only have excellent physical properties of graphite or carbon products but also have the characteristics of lightweight and easy processing.

We provide a full range of carbon-carbon composite materials, including CFC Fastener, CFC Plates, CFC U/L/H Profile, CFC Fixtures, CFC Cylinders, CFC Heaters, CFC Crucible, CFC Mold and more C-C Composite Materials. In addition, we also provide customization according to user needs and usage environment.

Applications

CFC is widely used in various fields such as metallurgy, heat treatment, semiconductors, photovoltaics, shipbuilding, and automotive.

We offer a wide range of carbon-carbon composite materials suitable for various applications, including vacuum furnaces and inert gas equipment, heat treatment, brazing, coating, sintering, and many other thermal processing applications across industries including metallurgy, heat treatment, semiconductors, photovoltaics, shipbuilding, and automotive.

- 1. Automotive – Apart from customized automotive parts fixtures, carbon-carbon composites are also used as high-performance automotive components, including brakes, clutches, and differentials.

- 2. Heat Treatment – Fixture systems endure significant thermal loads during heat treatment processes. Carbon-carbon (C/C composites) fixtures and components are ideal for such applications, often lasting over 5 years with no maintenance required. When considering weight reduction and component processing, the cost-effectiveness is significant.

- 3. Energy – As global demand for alternative energy increases, so does the need for manufacturers to produce more efficient equipment. To cater to this trend, we can provide high-standard carbon-carbon (C/C) composite components, including plates and fasteners, that are suitable for the conditions and speeds of modern high-energy equipment manufacturing.

- 4. Tools and Molds – Carbon-carbon (C/C) composites are crucial in various industries. Manufacturers of hard metal tools require robust and durable furnace supplies, including sintering trays. Carbon-carbon composites are the best materials for these high-demand processes. Additionally, the low wear characteristics of carbon-carbon composites make them widely used in mold manufacturing processes.

- 5. Semiconductors and Solar Energy – Carbon-carbon composites are highly regarded for their lightweight, chemical stability (corrosion resistance), and excellent heat resistance. In the semiconductor industry, they are primarily used for flat heaters and transportation robotic arms. In the solar/photovoltaic industry, they are mainly used for hot zone components and wafer carriers in silicon ingot production lines.

- 6. Biomedical and Healthcare – Carbon-carbon composites exhibit good compatibility and chemical inertness with living tissues. The processing of medical tools requires materials with excellent thermal shock resistance and heat resistance. The manufacture of medical equipment also necessitates robust and durable furnace supplies.

- 7. Glass and Ceramics – Products and materials made from carbon-carbon composites are increasingly used in the glass and ceramics industry. Glass processing requires materials with excellent thermal shock resistance and heat resistance. Some examples of the use of carbon-carbon composites include hot plates, sintering trays, and glass processing tools.

- 8. Rail Transit – Carbon-carbon composites are widely used as sliding plates for collecting electricity in rail systems. They maintain low resistance by combining carbon-carbon composites with copper alloys. Compared to metal plates, they exhibit extremely high stiffness, good wear resistance, high arc resistance, and reduced damage to power lines.

Carbon-carbon composites exhibit good compatibility and chemical inertness with living tissues. The processing of medical tools requires materials with excellent thermal shock resistance and heat resistance. The manufacture of medical equipment also necessitates robust and durable furnace supplies.