Carbon Carbon Composites – CFC Fasteners

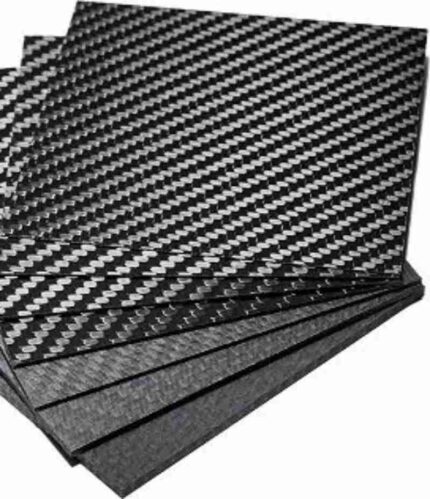

Carbon-carbon composites are high-performance composites consisting of carbon fibers and their fabric-reinforced carbon matrix. We supply a wide range of carbon-carbon composites products which includes CFC fasteners. C/C composite fasteners are crafted from carbon-carbon composites and are specially designed for connecting hot field fittings. It is lightweight, features excellent strength and elasticity, and can withstand high temperatures of up to 2000°C, demonstrating outstanding performance.

Features

CFC fasteners, widely used as components of high temperature heaters and vessels. They exhibit a variety of advantages over conventional engineering materials:

Structural stability, high tensile strength, high modulus, high strength, resistance to high temperatures and thermal shock, low coefficient of thermal expansion, low heat capacity, low density, excellent corrosion resistance, light weight, stable coefficient of friction, and good thermal and electrical conductivity.

These properties make CFC fasteners ideal for the manufacture of high temperature hot field components and friction components.

Applications

Carbon-carbon composite fasteners have a wide range of applications, including photovoltaic, semiconductor, vacuum heat treatment furnaces, high-temperature brazing furnaces, high-temperature sintering furnaces, and other industries.

These fasteners are particularly suitable for high-temperature and harsh chemical corrosive environments such as the semiconductor industry, high-temperature furnace materials, and other high-temperature equipment (e.g., exhaust, gaskets, bearings, etc.).

Carbon-carbon bolted fasteners exhibit a compelling array of excellent properties due to their low density, high-temperature resistance, corrosion resistance, good thermal shock properties, resistance to acids and alkalis, as well as resistance to friction and wear, and their ability to maintain excellent mechanical properties at high temperatures.

SHJ CFC Fasteners

Carbon-carbon composites have high strength and stiffness at high temperatures, which results in stable fastener performance and self-tightening in such environments.

Our CFC spring products are unique due to their exceptional properties. They are not only highly resistant to high temperatures and reusable like other C/C materials but also have excellent abrasion and touch resistance, in addition to high stiffness and toughness. Due to these qualities, our CFC spring products are widely used in numerous industries.

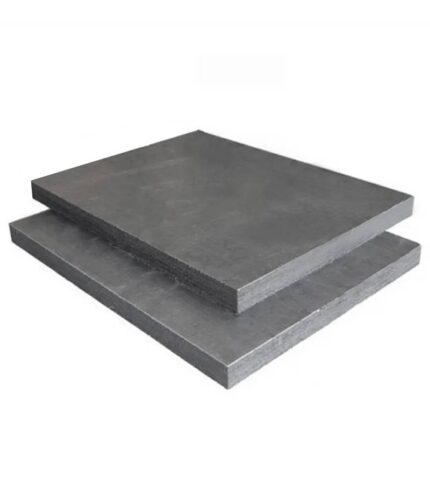

Our C/C composites have inherited graphite’s advantage of “no thermal deformation” and can be used many times without thermal damage, making them easy to move. In addition, we can produce CFC fasteners in different sizes and types to meet the diversified needs of the market according to the individual needs of our customers.

Our range of carbon-carbon composite fastener elements includes, but is not limited to:

- Screws and Nuts

- Threaded rods

- Bolts and pins

- Discs

- CFC Washer

- CFC Threaded Studs

- CFC Springs

- CFC Nuts

- CFC Round Nuts

- CFC Threaded Rods

- CFC Bolt

- CFC Rods

- CFC Rods

Specifications

| Material | C/C | C/C | C/C | C/C | |

| Bulk Density | g/cm³ | 1.3 | 1.4 | 1.45 | 1.6 |

| Compressive Strength | MPa | ≥100 | ≥150 | ≥150 | ≥150 |

| Flexural Strength | MPa | ≥120 | ≥120 | ≥150 | ≥150 |

| Tensile Strength | MPa | ≥60 | ≥80 | ≥80 | ≥100 |

| CTE | 10-6/℃ | ≤4 | ≤4 | ≤4 | ≤4 |

| Thermal Conductivity (@1000℃) | W/(m.k) | 20-30 | 20-30 | 20-30 | 20-30 |

| Ash | ppm | <200 | <200 | <200 | <200 |

*The parameters in this table are for standard products. If high purity products are required, purification treatment can be provided, with a purified ash content of ≤20PPM maximum.

*The above values are typical, not guaranteed.

*Special needs and high-end series products can be customized through negotiation and communication with our company.