Custom Vibration Graphite Block

In addition, this vibration molded graphite material has a number of properties, including heat resistance, electrical conductivity, corrosion resistance, good lubricating properties, light weight, low price, and ease of precision machining.

The Applications of Vibration Graphite:

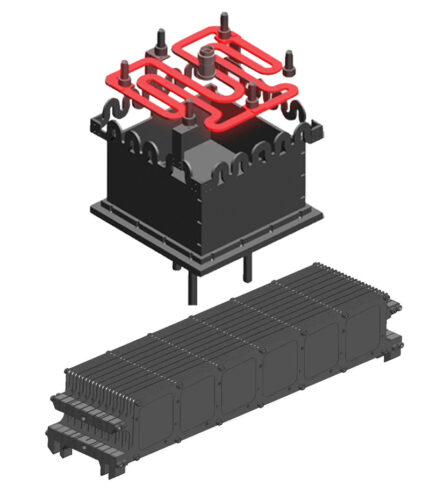

- heating element and Structural Components for vacuum furnace

In the modern material processing industry, a vacuum heat treatment furnace is a key piece of equipment that is widely used in metal, ceramics, powder metallurgy, and other fields. Graphite components, including heating elements, protective covers, and furnace plates made from specialty graphite material, play an important role in the heat treatment process of a vacuum furnace.

- Heat exchangers

Heat exchanger heat transfer components made of vibrated graphite material have excellent thermal conductivity, excellent corrosion resistance, non-pollution, high compressive strength and other characteristics. They are widely used as a substitute for stainless steel or other precious metals of Heat exchangers, effectively solving corrosion problems in equipment in the chemical industry and other fields.

- Powder metallurgy

SHJ provides the powder metallurgy industry with vibration molded graphite materials of consistent quality and stable performance for processing graphite products such as graphite boats and graphite molds

- Exothermic Welding:

During the exothermic welding process, the internal cavity temperature of the graphite mold increases rapidly to more than 2000 degrees Celsius. Therefore, the thermal shock resistance of graphite blocks materials plays a crucial role in this process. By using graphite materials with a low coefficient of thermal expansion and high thermal shock resistance provided by SHJ to manufacture the exothermic welding molds, not only does it improve the service life of the molds, but it also successfully avoids the risk of liquid metal leakage.

Physical specifications and dimensions

Physical Properties and Sizes

| Grade | MV-13 | |

|---|---|---|

| Material | Vibration Molded Graphite | |

| Specifications | Unit | Typical Value |

| Bulk Density | g/cm3 | 1.73 |

| Specific Resistance | μΩ.m | 8.5 |

| Compressive Strength | MPa | 35 |

| Flexural Strength | MPa | 15 |

| C.T.E. (RT-600°C) | 10-6/℃ | 3.3 |

| Thermal Conductivity | W/(m.k) | 130 |

| Ash Content | % | 0.12 |

| Maximum Grain Size | mm | 0.8 |

| Size | Φ850×650mm, Φ920×640mm Φ1000×590-660mm, Φ1120×410mm Φ1120×590mm, Φ1270-×410mm Φ1270×600mm, Φ1300×600mm Φ1420×410-590mm, Φ1590×590mm |

|

| Grade | MV-12 | |

|---|---|---|

| Material | Vibration Molded Graphite | |

| Specifications | Unit | Typical Value |

| Bulk Density | g/cm3 | 1.72 |

| Specific Resistance | μΩ.m | 9 |

| Compressive Strength | MPa | 30 |

| Flexural Strength | MPa | 13 |

| C.T.E. (RT-600°C) | 10-6 /℃ | 3.2 |

| Thermal Conductivity | W/(m.k) | 100 |

| Ash Content | % | 0.2 |

| Maximum Grain Size | mm | 0.8 |

| Size | 500*500*2050mm, 400*400*2050mm | |

These properties are typical values and not guaranteed.

Advantages of SHJ Graphite Block Manufacturer

SHJ has many years of experience in researching graphite materials both at home and abroad, and is familiar with the physical properties of various materials as well as their advantages and disadvantages, as well as having a comprehensive database.

As a result, SHJ as a graphite manufacturer is able to provide customers with multifaceted solutions, including material optimization, substitution and performance enhancement. For example, in the powder metallurgy industry such as vacuum sintering of cemented carbide and high temperature heat treatment, SHJ assists customers in selecting cost-effective graphite materials and provides the necessary technical support to meet their needs.

Our company can develop and produce custom specialty graphite to provide customers with personalized solutions.