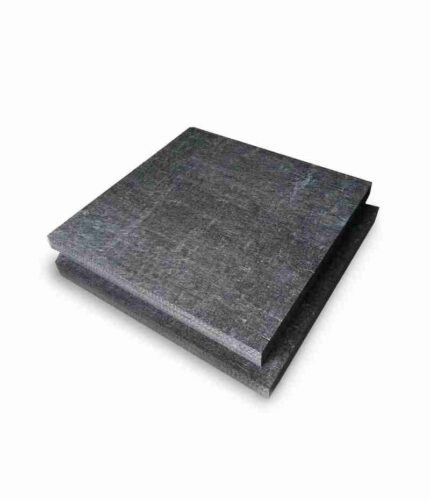

Graphite Crucible for Aluminum

Graphite Crucible for Aluminum

Vacuum aluminized graphite crucible is usually used in the form of groups, a group generally contains 24 crucible. We are constantly striving for uniformity and longer service life of crucible.

The graphite crucible we provide for aluminum has the characteristics of high temperature corrosion resistance of molten aluminum, high temperature oxidation resistance, rapid cooling and thermal stress damage resistance, and is an indispensable key multi-consumable component for vacuum aluminum plating. The product quality is stable and has won the high trust of customers.

Vacuum aluminum evaporation is a process by directly heating molten aluminum in a vacuum environment to vaporize it into aluminum vapor and evaporate it on the surface of a plastic film. In this process, graphite materials are widely used because of their compact structure and high strength.

Graphite crucible machining steps:

| 1. Sawing | 2. Turning | 3. Milling | 4. Grinding | 5. CNC |

|---|

Product features:

In order to ensure good thermal shock resistance, in the production of graphite crucible for aluminum, we use high-density, low porosity graphite material, and ensure that there is a low coefficient of thermal expansion. The products produced by our company have excellent characteristics such as high purity, high strength, high density, density of 1.9g/cm3, low porosity, tight structure, becoming the ideal choice of aluminum evaporation crucible.

SHJ has a number of machining lines, which can be customized according to the drawings provided by customers to meet different precision requirements, while choosing the most cost-effective processing technology in the shortest processing time. We are committed to providing customers with high quality aluminum graphite crucible to help the production process more efficient.