Isostatic Graphite For Copper Continuous Casting

Due to the advantages of simplifying the casting process, improving product qualification rate, and homogenizing product organizational structure, the production of non-ferrous metal plates, tubes, rods, etc. using continuous casting and rolling has become very common. Among them, the crystallizer that plays a crucial role in product quality is made of isostatic pressing graphite material. Isostatic pressure graphite materials have excellent properties in heat conduction, thermal stability, self-lubrication, anti-wetting, and chemical inertness, making them an irreplaceable material for making crystallizers.

| Grade | Bulk Density | Specific Resistance | Flexural Strength | Compressive Strength | Ash (Normal Grade) | Ash (Purified) | Grain Size | Regular Size |

|---|---|---|---|---|---|---|---|---|

| g/cm³ | μΩ.m | MPa | MPa | ppm | ppm | μm | mm | |

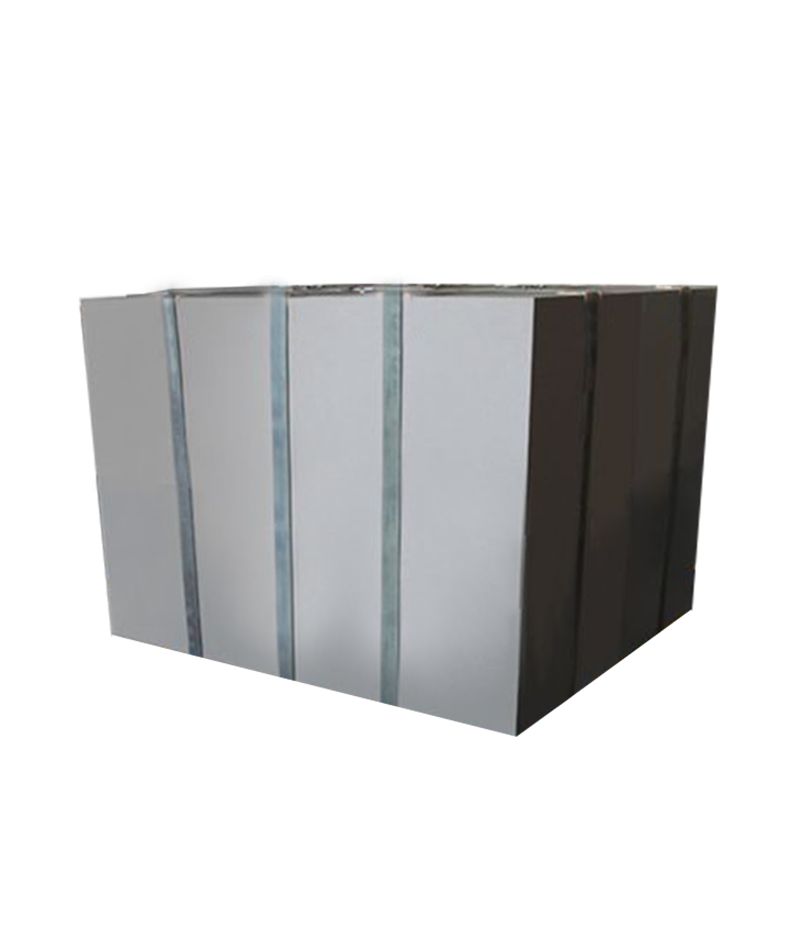

| IS-14 | 1.86 | 11~12 | 65 | 135 | 500 | 50 | 5 | 1200*640*270 1600*670*300 |

| IS-41 | 1.78 | 15 | 65 | 130 | 200 | N/A | 10 | 620*520*260 900*570*260 |

| IS-42 | 1.78 | 14 | 65 | 110 | 200 | N/A | 13-15 | 510*310*250 620*520*250 740*740*230 |

Forming of Isostatic Graphite

Unlike ordinary extrusion and molding, isostatic pressing graphite is formed using cold isostatic pressing technology. Fill the raw material powder into the rubber mold, and compact the powder through high-frequency electromagnetic vibration. After sealing, vacuum the powder particles to

exhaust the air between them. Place it in a high-pressure container containing liquid media such as water or oil, and pressurize it to 100-200 MPa. Press it into a cylindrical or rectangular product. According to Pascal’s principle, pressure is applied to a rubber mold through a liquid medium such as water, and the pressure is equal in all directions. In this way, the pressed powder particles in the mold are not oriented according to the filling direction but compressed in an irregular arrangement. Therefore, although the graphite is anisotropic in crystallography, the isostatic pressing graphite is isotropic on the whole. The formed products not only have cylindrical and rectangular shapes but also cylindrical and crucible shapes.

Advantages of SHJ Isostatic Graphite Materials

SHJ isostatic pressing graphite material has a series of excellent properties. For example, isostatic pressing graphite has good heat resistance. In an inert atmosphere, its mechanical strength not only does not decrease with the increase of temperature, but also increases, reaching its highest value at around 2500 ℃; Compared with ordinary graphite, its structure is fine and dense, and its uniformity is good; The coefficient of thermal expansion is very low, with excellent thermal shock resistance; Isotropic; Strong chemical corrosion resistance, good thermal and electrical conductivity; Has excellent mechanical processing performance.