Graphite Heat Exchangers

Graphite heat exchangers are the most widely used and typical chemical unit equipment among graphite devices. The development of graphite heat exchangers has been very rapid. A large number of high-performance graphite heat exchangers are used in processes involving various media such as hydrochloric acid, sulfuric acid, and citric acid, except for strong alkalis and strong oxidizing agents.

They are widely used in the chemical industry, food industry, and many other industrial sectors, primarily for heating, cooling, condensation, and evaporation operations. Due to their excellent thermal conductivity, superior corrosion resistance, and non-contaminating properties, graphite heat exchangers have largely replaced those made of stainless steel or other precious metals, solving many corrosion resistance problems in the chemical and other industries.

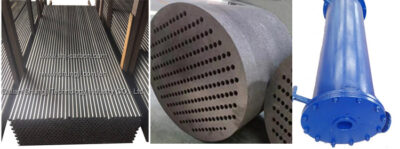

Graphite heat exchangers can be classified by their structural form into several types, including shell and tube, block hole, spray, and immersion types. Among these, shell and tube and block hole graphite heat exchangers are the most widely used. Additionally, based on their application in process operations, they can be categorized into evaporators, heaters, coolers, condensers, and more.