Spectral Analysis Graphite Electrode

We produce the extruded graphite rods and purify them to ash content less than 2PPM for application of spectral analysis graphite electrode. The normal diameters of our high purity spectral graphite rod is 6mm, 8mm, 10mm, 13mm and 15mm, the standard length is 300mm.

Spectral Analysis Graphite Electrode – Pure Graphite Rod Ash

We produce the extruded graphite rods and purify them to ash content less than 2PPM for application of spectral analysis graphite electrode. The normal diameters of our high purity spectral graphite rod is 6mm, 8mm, 10mm, 13mm and 15mm, the standard length is 300mm.

Specifications

| Grade | Bulk Density | Specific Resistance | Flexural Strength | Ash (purified) | Grain Size |

| g/cm³ | μΩ.m | MPa | ppm | mm | |

| FE-P-0 | ≥1.68 | 8 | 30 | 2 | 0.045 |

| FE-P-1 | ≥1.68 | 8 | 30 | 5 | 0.045 |

| FE-P-2 | ≥1.68 | 8 | 30 | 10 | 0.045 |

Note: These are reference data, not guaranteed data.

Product Description

Spectral rod refers to a special graphite pure rods used for spectral analysis. Graphite can be used for spectrochemical analysis of all elements except carbon, emission spectrum, atomic absorption spectrum, gas analysis and other fields. The spectral analysis graphite electrode uses low ash high-quality petroleum coke as raw material, which is calcined, crushed, kneaded, baked, impregnated, graphitized and purified. At present, we can generally achieve ash content ≤ 5PPM, and adopt clean room dust-free packaging to ensure that the products meet the high purity requirements of spectral analysis applications.

We have many sizes of conventional specifications, such as ∮6*300, ∮8*300, ∮10*300, ∮13*300, ∮15*300, etc., which are convenient for customers to choose.

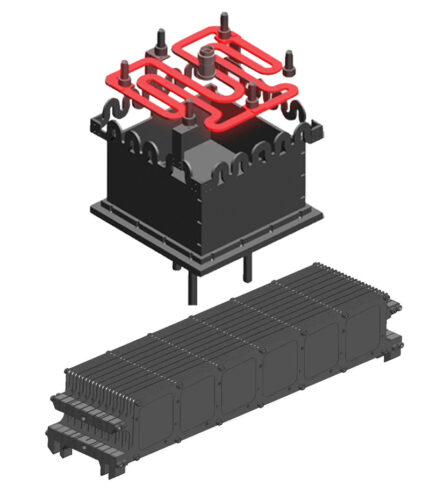

Production Process

| 1. Solid Raw materials | 2. Crushing, Milling | 3. Screening | 4. Dosing |

| 5. Mixing, Kneading | 6. Extruding | 7. Baking | 8. Pitch Impregnation |

| 9. Rebaking | 10. Graphitization | 11. Purification | 12. Inspection |

Packaging And Delivery

Customized packaging of spectral analysis graphite electrode according to customer needs, wooden box, pallet packaging methods are available.

According to the cargo weight and delivery requirements, choose the most cost-effective transportation method, express, sea, airway, railway, multimodal transportation are available.