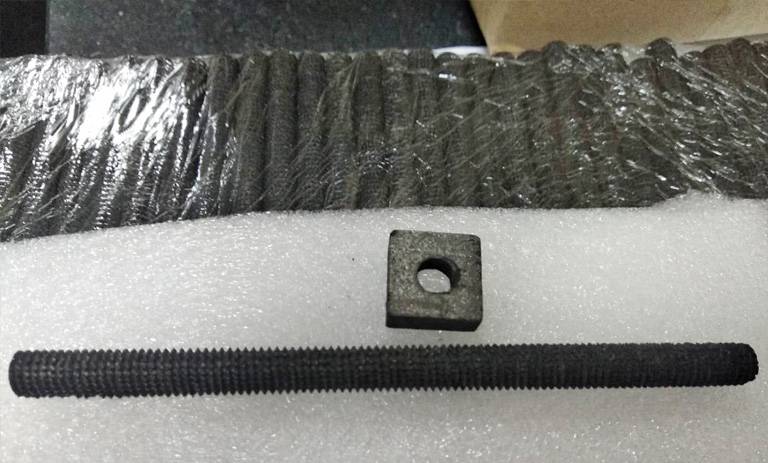

What Are Carbon Carbon Composite Materials?

C/C composites are a type of advanced materials reinforced with high-strength carbon fibers, exhibiting superior properties such as lightweight construction, low thermal expansion coefficient, excellent fracture toughness, wear resistance, ablation resistance, and high elasticity. Due to their unique characteristics, our C/C composites find extensive applications in various fields, including semiconductors, photovoltaics, electronics, metallurgy, chemicals, medical, and automotive industries.

Key Advantages of C/C Composites

- High Mechanical Strength, Elasticity, and Toughness:

Compared to graphite materials, C/C composites offer higher strength and bending resistance, along with enhanced crack resistance and spalling resistance.

- Exceptional Heat Resistance:

Under high-temperature conditions, C/C composites demonstrate superior strength compared to metallic materials. These materials can even be used in ultra-high-temperature inert atmospheres of 2000°C or above.

- Lightweight and Easy to Handle:

Compared to metallic materials, C/C composites possess a lower density, making them suitable for lightweight design applications.

Carbon-Carbon (C/C) composites, with their lightweight, low thermal expansion coefficient, high-temperature resistance, corrosion resistance, stable friction coefficient, and excellent thermal and electrical conductivity, are not only suitable for manufacturing high-temperature thermal field components but also the ideal choice for friction components. They are widely used in semiconductors, aerospace, and braking systems.

Our main products include carbon felt, C/C composites, and graphite materials, which can be customized to meet the specific needs of different industries.

Over the years, we have gained significant advantages in technical support, product performance enhancement, and cost reduction.